By Skywurz |

So if you are just tuning in things started in this thread https://www.ducatisupersport939.net/forum/385-wheels-tires/15742-plug-patch.html where i found that most places wont patch tires.

I went with a plug option but have had issues in the past with old school string plugs eventually drying and falling out. This was mostly on ATVs but this would be catastrophic and possibly deadly on a sports bike. I found a type of plug that has been around for awhile but i had never seen before. This was the Mushroom Plug. I hate name and brand dropping but i bought this Kit by Stop and Go on Amazon http://a.co/d/2eZ5Fry as well as this rubber cement by Slime http://a.co/d/1yWardO . I went with the hard case because it is nice to put on the shelf in the garage and did not intend to carry it wit me. Now this plug says it does not need rubber cement but i figured it could not hurt and was cheap insurance. I currently have around 400 miles on my plug and have put it through its paces. I have not had any air loss. The instructions and regulations say that plugged tires are temporary fixes and should only be run up-to 50 miles at speeds up-to 55mph. Use all instructions and advice here at your own risk.

As you can see this is a standard size hole and its in a prime location for plugging. I was worried at first that the belts were not that far over. With the probe tool i found the belts were there. The belts help hold the plug and the areas with the belts dont flex as much so the plugs can stay in. Side walls or spots are too far out on the side of the tires should not be plugged or patched.

The little bugger that i pulled out of the tire.

Follow the instructions with your kit but i will show some pictures of my steps. Here you can see me probing the tire and inspecting the damage and widening things out so i can get the reamer in. Here i feel the belts so i feel good about the process.

Next I Ream out the hole. I spend a good amount of time here making sure the hole is good and smooth and i get some metal dust and belt parts coming out. I had read stories about belts cutting the plugs if not cleaned up properly then causing rapid deflation.

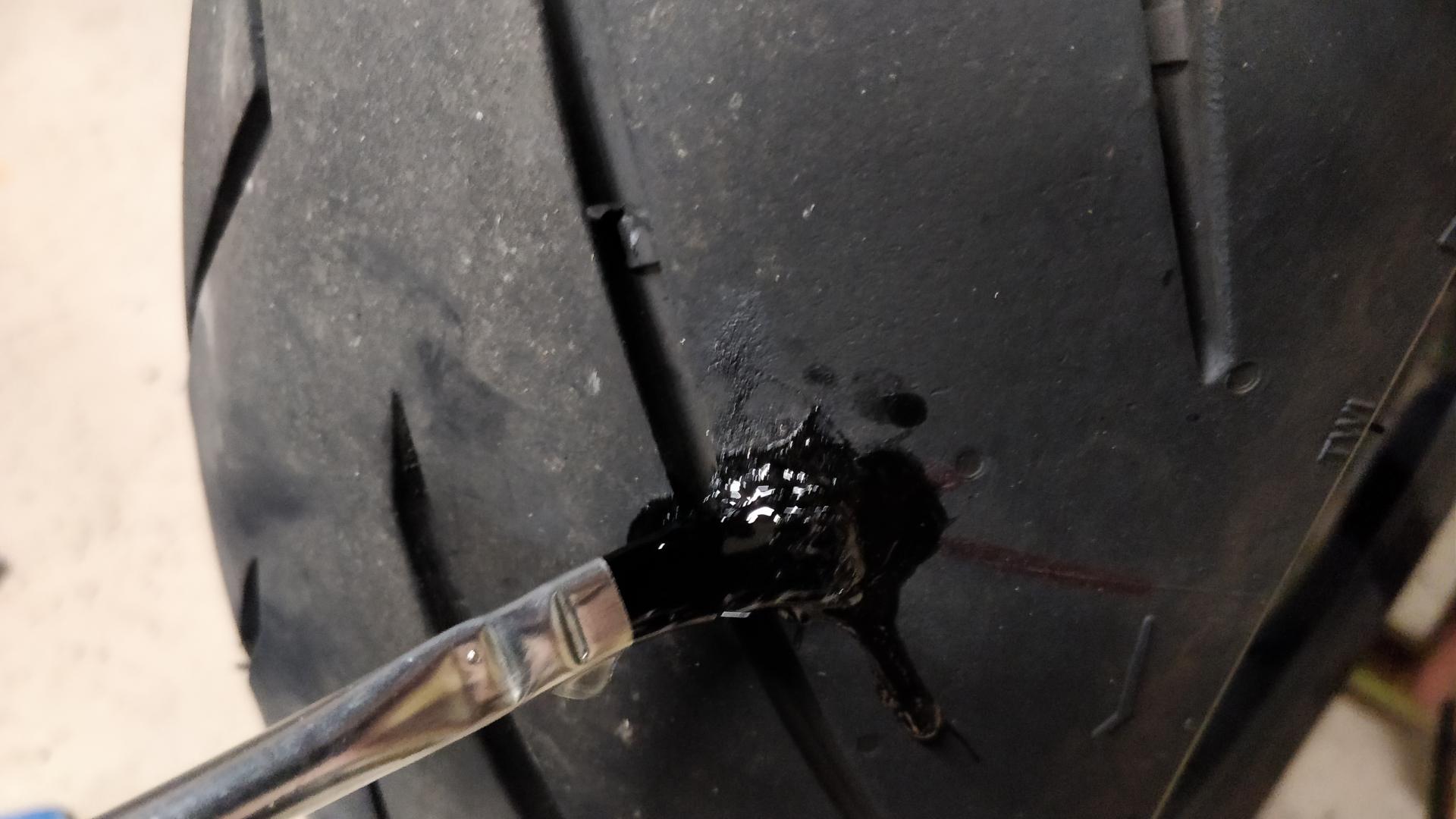

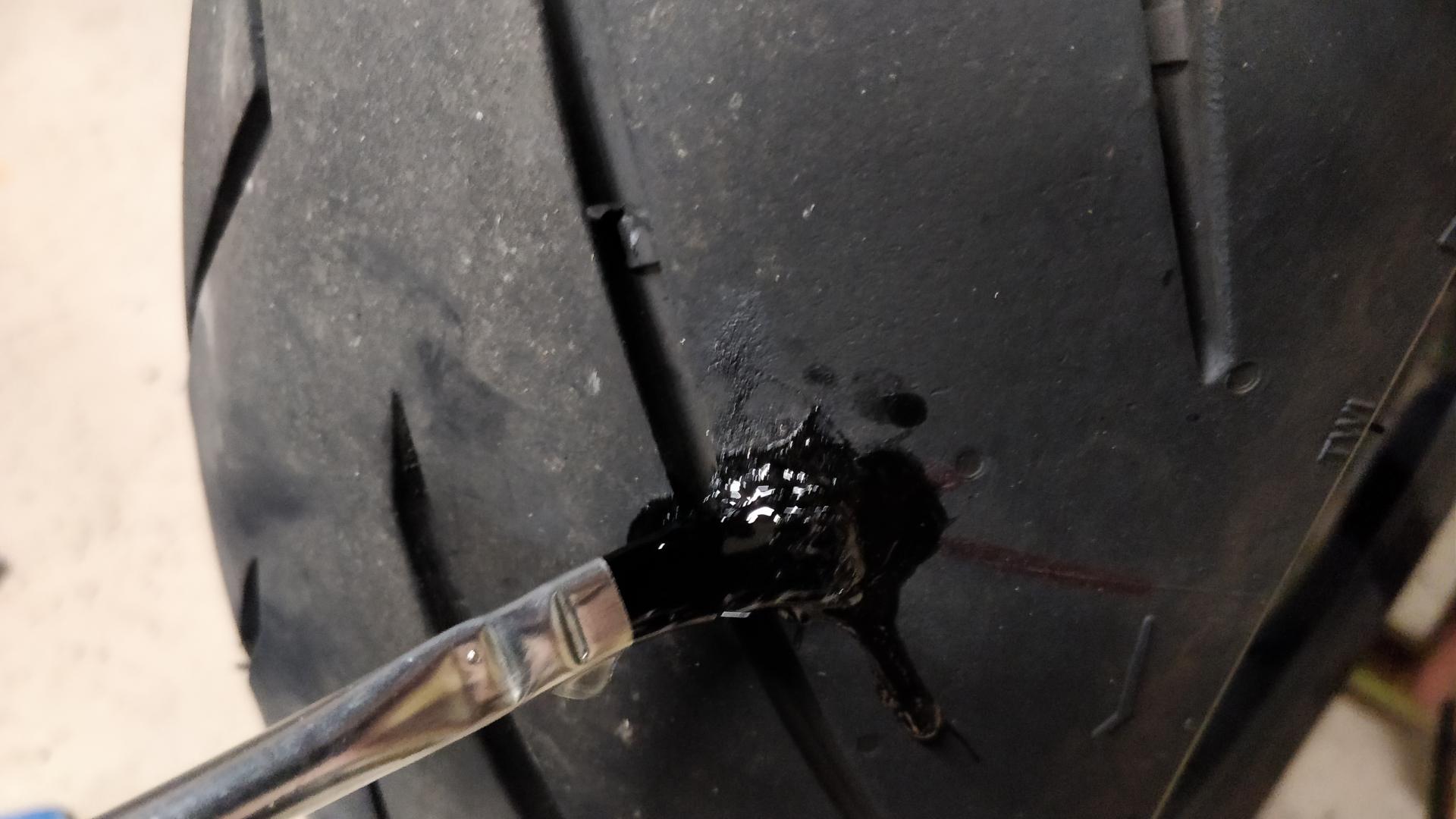

Here i put on the rubber cement trying to get it in the hole. The instructions say this is not needed however it made me feel better **The Feels**

I insert the nozzle of the plug gun into the hole.

I attach the plug gun and inject the plug.

Ok now the plug is in the hole.

I filled the tire with air and set the plug with pliers.

Next we cut the plug flush with the tread.

Add a little more cement for the feels. I dont see bubbles or leaks so i feel pretty good about this.

boom! All done! let the cement dry for a few hours and check the air pressure.

As you can see this is a standard size hole and its in a prime location for plugging. I was worried at first that the belts were not that far over. With the probe tool i found the belts were there. The belts help hold the plug and the areas with the belts dont flex as much so the plugs can stay in. Side walls or spots are too far out on the side of the tires should not be plugged or patched.

The little bugger that i pulled out of the tire.

Follow the instructions with your kit but i will show some pictures of my steps. Here you can see me probing the tire and inspecting the damage and widening things out so i can get the reamer in. Here i feel the belts so i feel good about the process.

Next I Ream out the hole. I spend a good amount of time here making sure the hole is good and smooth and i get some metal dust and belt parts coming out. I had read stories about belts cutting the plugs if not cleaned up properly then causing rapid deflation.

Here i put on the rubber cement trying to get it in the hole. The instructions say this is not needed however it made me feel better **The Feels**

I insert the nozzle of the plug gun into the hole.

I attach the plug gun and inject the plug.

Ok now the plug is in the hole.

I filled the tire with air and set the plug with pliers.

Next we cut the plug flush with the tread.

Add a little more cement for the feels. I dont see bubbles or leaks so i feel pretty good about this.

boom! All done! let the cement dry for a few hours and check the air pressure.